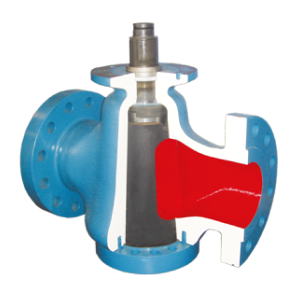

PR-Plug Valves for Cement Plants

We have designed a new valve which is specially suited for mediums that consist of very abrasive/corrosive particles dissolved in fluids. The valve has proven to be extremely wear resistant under the testing that has been performed on site, in actual working conditions. This makes the valve a very attractive alternative to, for example, the more expensive "Stellite" coated valves.

The valve has the following advantages:

- Hardened plug specially ground and individually fitted into the seat of the housing. This ensures a longer lifetime in as much as the erosive particles in the fluids are "scrapped off" when the valve is manoeuvred (instead of being trapped in a gap between plug and housing).

- The special precision grinding and seating of the plug to the seat of the valve ensures that the valve is "tight" without the use of lubricants. This gives a very wear resistant metal to metal sealing.

- Despite the fact that only ordinary steel is used for the main components of the valve, the valve has proven to be extremely wear resistant. This makes the valve a great, less expensive alternative compared to the more expensive "Stellite" coated valves (valves with hard facing).

- The valve is designed so that it can easily be refurbished, due to the fact that the valve seat is manufactured with extra material thickness. During refurbishing the valve seat is machined and the plug re-fitted.

- General robust design. The seal between the plug and housing contains no "fragile" moving parts in combination with the sealing rings (as for example, can be found in a ball valve).

- Large sealing seat area compared to what you find in a ball valve.

General valve design features:

- Pressure balanced taper plug valve

- Metal seated plug valve

- The plug is adjustable in the body seat by means of a blow- out proof adjustment screw situated in the bottom cover

- case hardened and P.T.F.E. coated

- Cylindrical anti blow-out stem with three unique seals

- Smooth shape valve bore - low pressure drop

- The valve flow is bidirectional

- 90 degree turning of the plug to open / close the valve

- Fire safe according to API 6FA, BS 6755 part 2 and ISO 10497 Anti-static design

- Valves are available in a wide range of variants as described In the valve standards