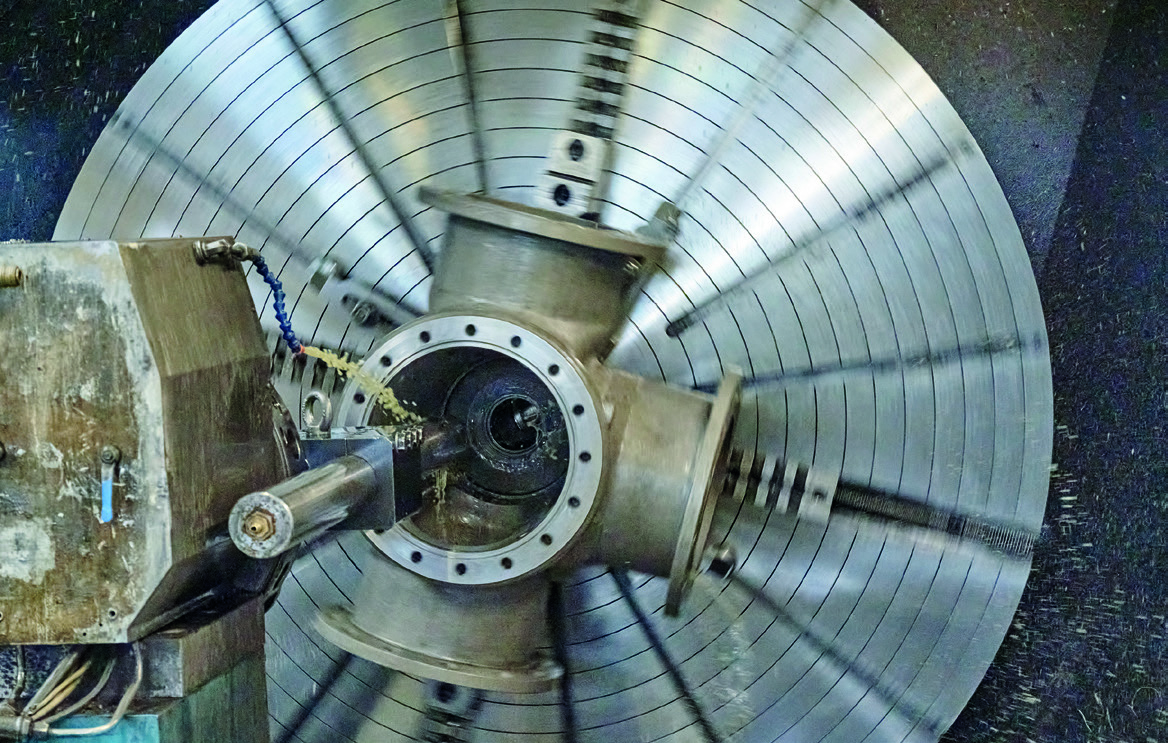

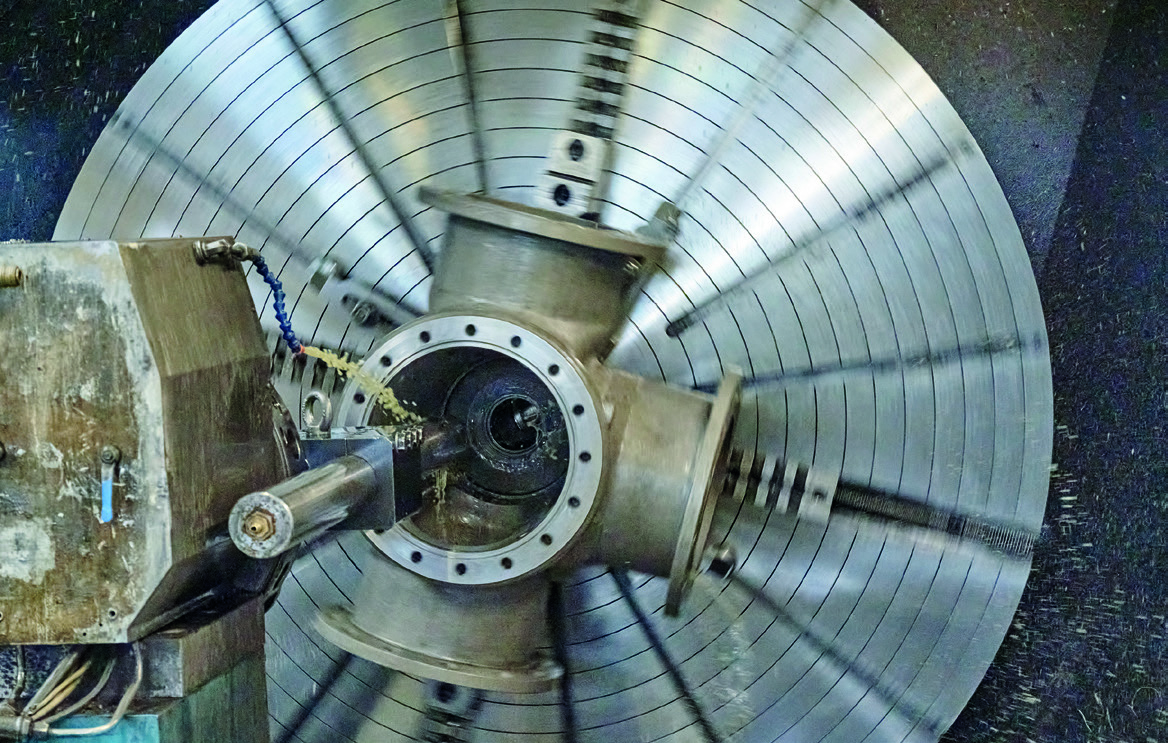

Reparation / maintenance of industrial plants

We can offer you our services at short notice and without bureaucracy.

All repairs are carried out in accordance with our quality assurance system and documented accordingly.

We can offer you our services at short notice and without bureaucracy.