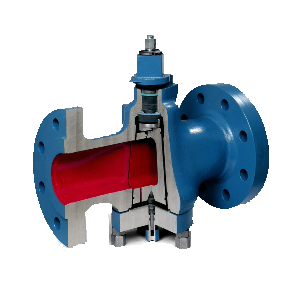

High Pressure PR Lubricated Plug Valve

High pressure PR lubricated valves are the ideal shut-off device for almost any medium, even under the most severe operating conditions. They are used in all those places where fast, troublefree and positive sealing is required. The design is very compact, it requires little space to install, and can be mounted in any position. The basic operation of the PR valve is very s imple, as the only moving part is the plug. In open plug position the passage area is free and in line with the pipe line. On turning the plug through 90° to closed valve position, the pass age is shut off, thus providing efficient closure.

Main Features

- Pressure balanced design

- Sizes from ½" to 36"

- Classes: #150 to #2500

- Up to 30° seating area

- Fully protected seating area

- Few moving parts

- Primary seals: metal to metal

- Secondary seals: lubricant

- Minimal body cavities

- End connections as desired (Flange, Clamp, Welding ends etc...)

- Broad selection of materials

- 90° turning of the plug to open/close

- Low operating torque

- Direct or worm gear operation

- Vertical or horizontal gear - operating stem

- Can be installed in any position required

Plug/Steam

The plug and the operating stem are two separate parts, which are connected by means of the equalizer disc through a strong driving tang and slot arrangement.

This way the plug "floats" i.e. the pressure of the medium is exercised equally on the top and the bottom of the plug, and an axial pressure balance by internal borings of the plug is allowed. This also ensures that the plug is free to move in the direction of the closed-off port of the body; furthermore, the operating stem will not jam causing leakage.

To get a low friction between plug and body, the plug is PTFE coated.

Correct adjustment of the plug up to the taper seat of the valve body is done by means of the pressure screw, which is placed in the bottom cover.

Lubrication System

The PR valve is furnished with a lubrication system which allows feeding special lubricant into the valve. On lubrication, the grease is forced into a groove system where from it is distributed between the seating faces of the valve body and those of the plug, forming a sealing and corrosion preventive lubricating film.

The plug is therefore surrounded by grease on all surfaces which besides the two advantages already mentioned provides for smooth-acting control even after long periods of service interruption.

Sealing to the outside

The tightness between the body and the operating stem is provided by three independent seals. The first prevents penetration of water, dirt, etc. from outside into the stem bearing.

The second is a PTFE sealing ring with an embedded spring of Stainless Steel or Hasteloy C. This ring ensures optimum safety even in the presence of extreme pressure and temperature variations.

The ring can be replaced from outside.

The third seal is of PTFE, depending on the application of the valve. In order to reduce the torque requirement, the bearing surface between the operating stem and the neck of the valve body is provided with a thrust made of PTFE of high load capacity and low friction coefficient.

The operating stem is provided with an operating square, held in place by the stem nut and a parrallel key. The bottom cover is bolted on the body and the gasket is placed in a groove, which secures it against blow out by higher pressure.

Operating can be done manually with wrench direct or by a gear exchange.

Furthermore all PR valves can be provided with various forms of automatic operation (electric, pneumatic or hydraulic).