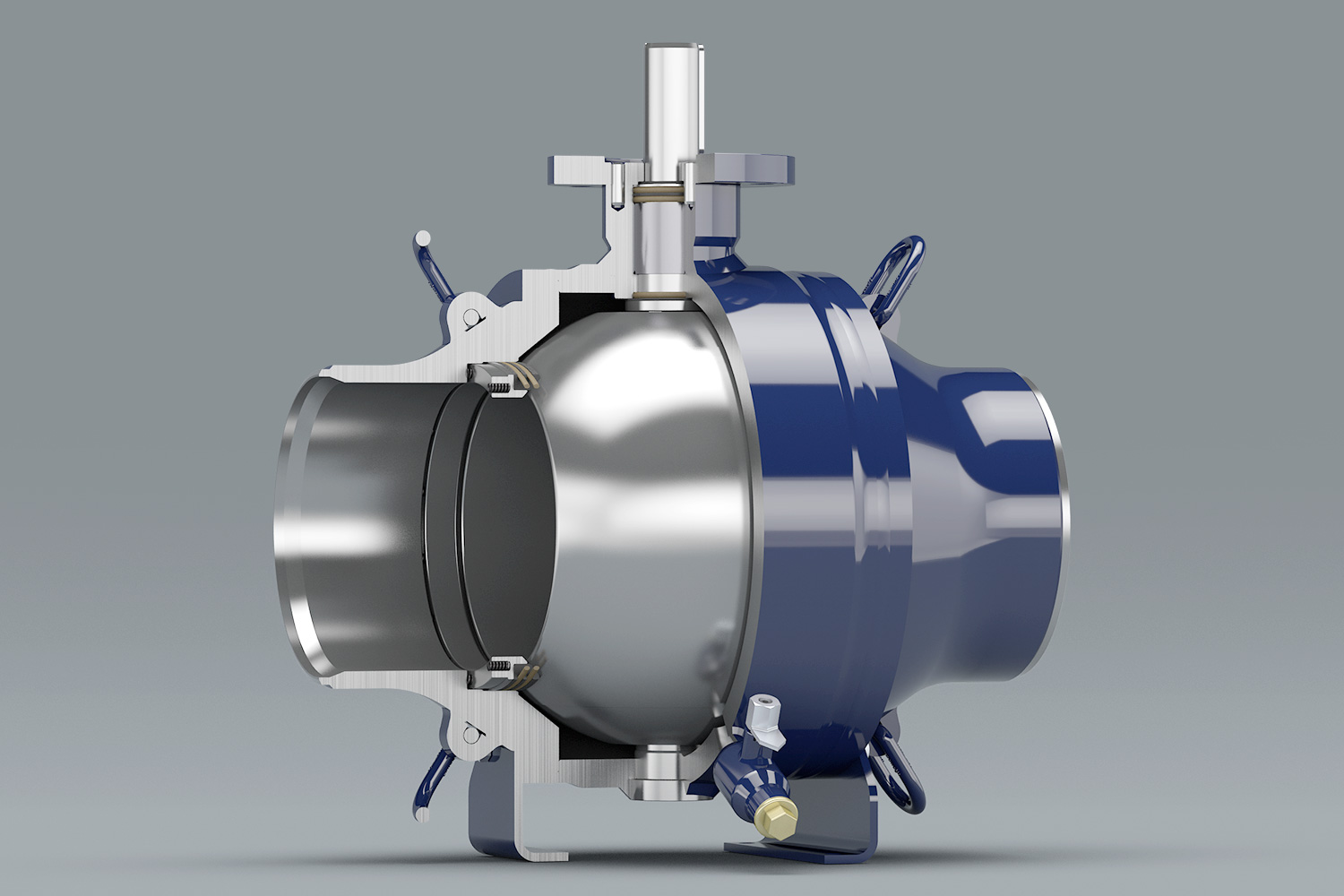

Vexve trunnion-mounted ball valves

Ball valve with trunnion-mounted ball made of steel or stainless steel, can be used for all non-aggressive media, such as district heating, heating hot water, air-conditioning cold water, oil and compressed air.

Ball valves with trunnion mounting

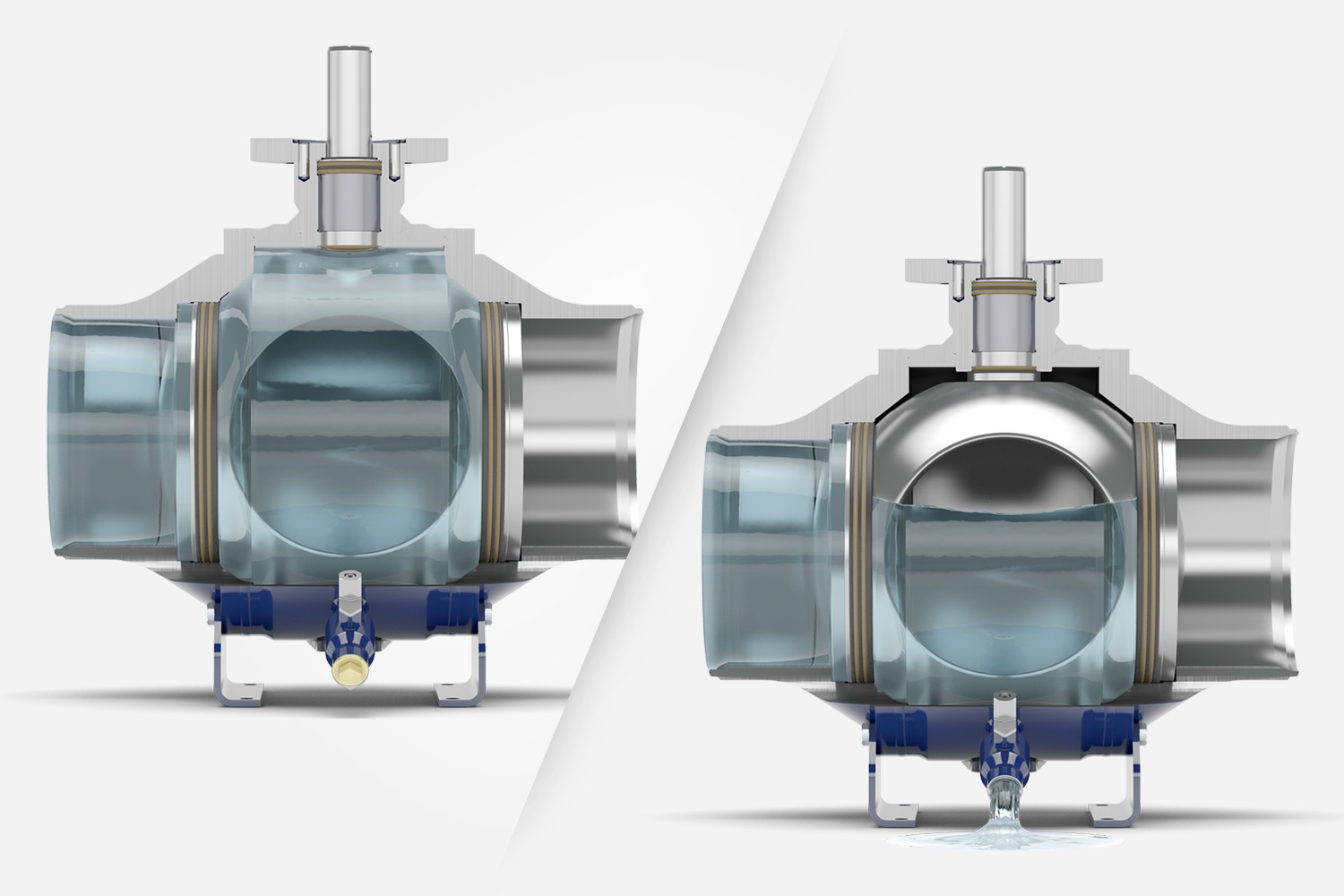

Double Block & Bleed

The "Double Block & Bleed" function allows the housing to be drained in order to check the tightness of the ball valve, even when the pipeline is under pressure. Draining of the housing is possible in both positions - open or closed.

The tightness test of the ball valve can be carried out with the "Double Block & Bleed" function as follows. The medium flows through the ball valve when it is in the open position. The seals ensure that the ball valve is tight. The tightness of the ball valve can be checked by closing the ball valve and draining the accumulated medium from the cavity. After the ball cavity is empty, you can check the tightness of the ball valve.

Nominal widths / Connection types

Our trunnion mounted ball valves are available in nominal sizes DN150 to DN900 and the following connection types:

- Welding end / Welding end

- Flange / Flange

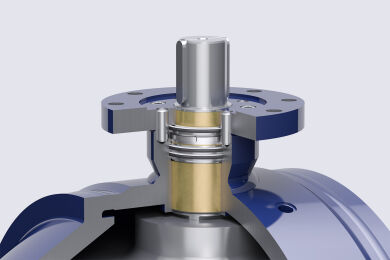

Stem construction

Single-Pistion-Effect

The ball sealing seats use the Single Piston Effect (SPE), which enables the seats to automatically relieve increased pressure inside the ball valve from the dead space into the pipeline.

The pressure in the dead space can increase due to temperature changes, for example.

Data sheet / information / downloads

Interested in our products? Please contact us!

Or via our contact form.