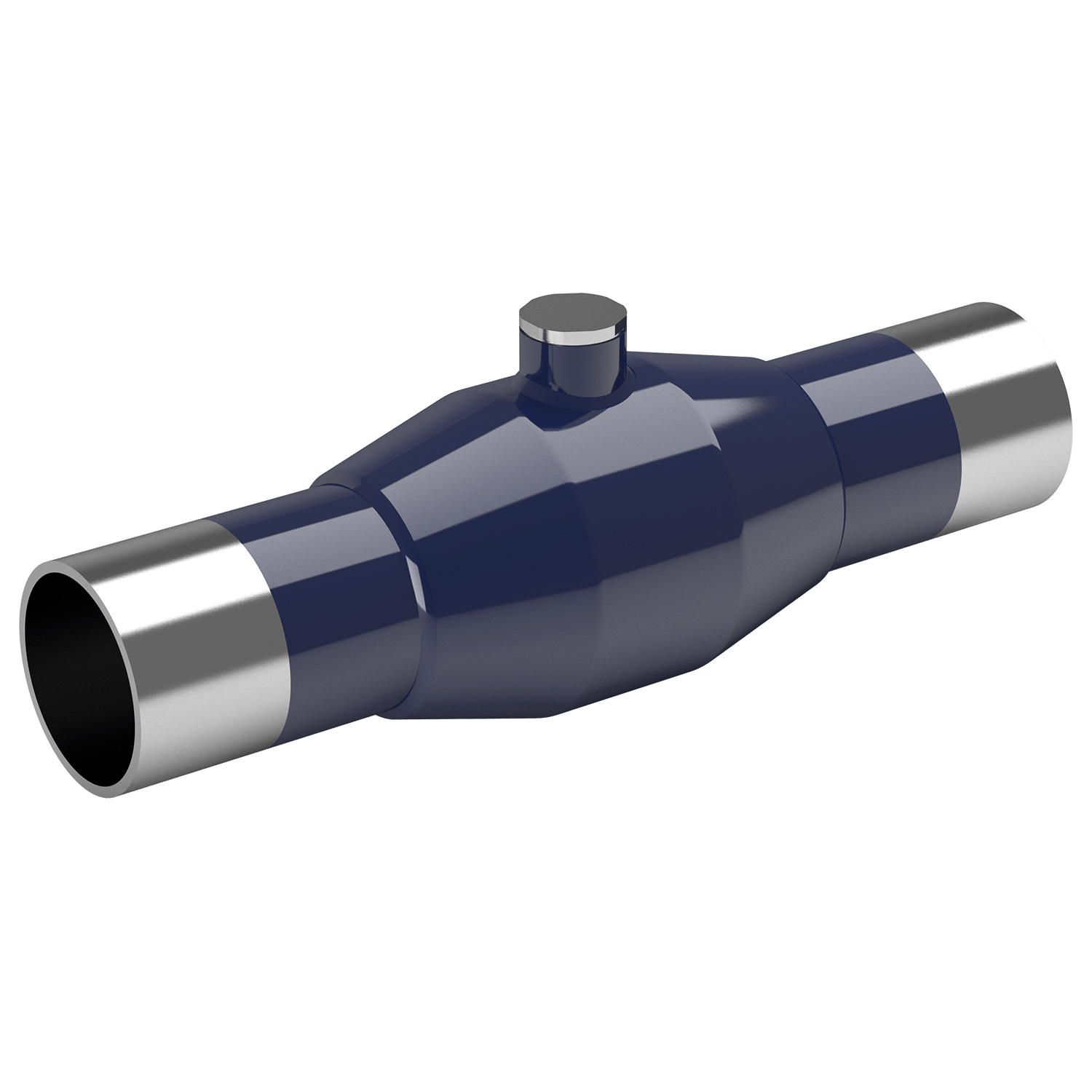

Bedarfsanschlusshahn / Einmalkugelhahn

Der Bedarfsanschlusshahn - auch Einmalkugelhahn genannt - von Vexve (Typ NAVAL) ist einsetzbar für alle nichtaggressiven Medien, wie z.B. Fernwärme, Heizwarmwasser, Klima-Kaltwasser, Öl und Druckluft.

Bedarfsanschlusshahn/Einmalkugelhahn Vexve (Typ NAVAL) Vorteile

- Gute und kostengünstige Isolierbarkeit

- 90° Auf-/Zu-Anschlag

- Betätigung mittels Außen-Sechskant

- Dreifache Spindelabdichtung

- DN20 bis DN200

Bedarfsanschlusshahn/Einmalkugelhahn Konstruktion

Das gesamte Gehäuse und die Anschlussteile der Bedarfsanschlusshähne sind miteinander verschweißt. Am Hahnkörper gibt es keine undichten Flansch- und Schraubverbindungen. Die ausblassichere Spindel wird mit zwei O-Ring-Dichtungen und mit einer durch Mediumdruck angepressten graphitverstärkten PTFE-Scheibe nach außen abgedichtet. Dadurch kann der Bedarfsanschlusshahn, auch nach Anschluss des neuen Abgangs, als „normale“ Armatur verwendet werden und muss somit nicht eine verlorene Armatur werden.

Die Deckelschraube kann sowohl geschraubt als auch verschweißt (empfohlen) werden. Der Einmalkugelhahn verfügt über einen Auf-/Zu-Anschlag, welcher eine 360° Betätigung verhindert.

Einfache und zuverlässige Betätigung über Außen-Sechskant.

Bedarfsanschlusshahn/Einmalkugelhahn Eigenschaften

Der Bedarfsanschlusshahn/Einmalkugelhahn von Vexve (Typ NAVAL) ist wartungsfrei. Keine Stopfbuchse, kein Nachschmieren. Hohe Lebensdauer. Durch geringes Gewicht schnelle und leichte Montage. Niedrige Betriebskosten durch geringen Widerstand. Kostengünstige, durchgehende Isolierbarkeit. Durch Verwendung von hochwertigen Rohmaterialien keine Gusslunkerstellen.

Bedarfsanschlusshahn/Einmalkugelhahn Ausführungen

- Beidseitig Anschweißenden

Bedarfsanschlusshahn/Einmalkugelhahn – verfügbare Nennweiten

- DN20 - DN250 (reduzierter Durchgang)

- DN25 - DN200 (voller Durchgang)

Bedarfsanschlusshahn/Einmalkugelhahn Verwendung

Ein Einmalkugelhahn bzw. Bedarfsanschlusshahn dient zum Abschluss eines Bauabschnittes, der zu einem späteren Zeitpunkt weitergeführt wird. Als Endstück eingeschweißt, kann die vorhandene Trasse jederzeit fortgeführt werden, ohne dass die Rohrleitung entleert und außer Betrieb genommen werden muss.

Einmalkugelhähne werden wie ein Stück Rohr in geschlossener Stellung in die Trasse eingeschweißt.

Zum Schutz vor Verunreinigungen und, um zu verhindern, dass PUR-Schaum in das offene Ende der Einmalkugelhähne eindringt, ist die Montage eines Klöpperbodens bzw. einer Rohrkappe nach DIN 2617 vorgesehen.

Datenblatt / Informationen / Downloads

Interested in our products? Please contact us!