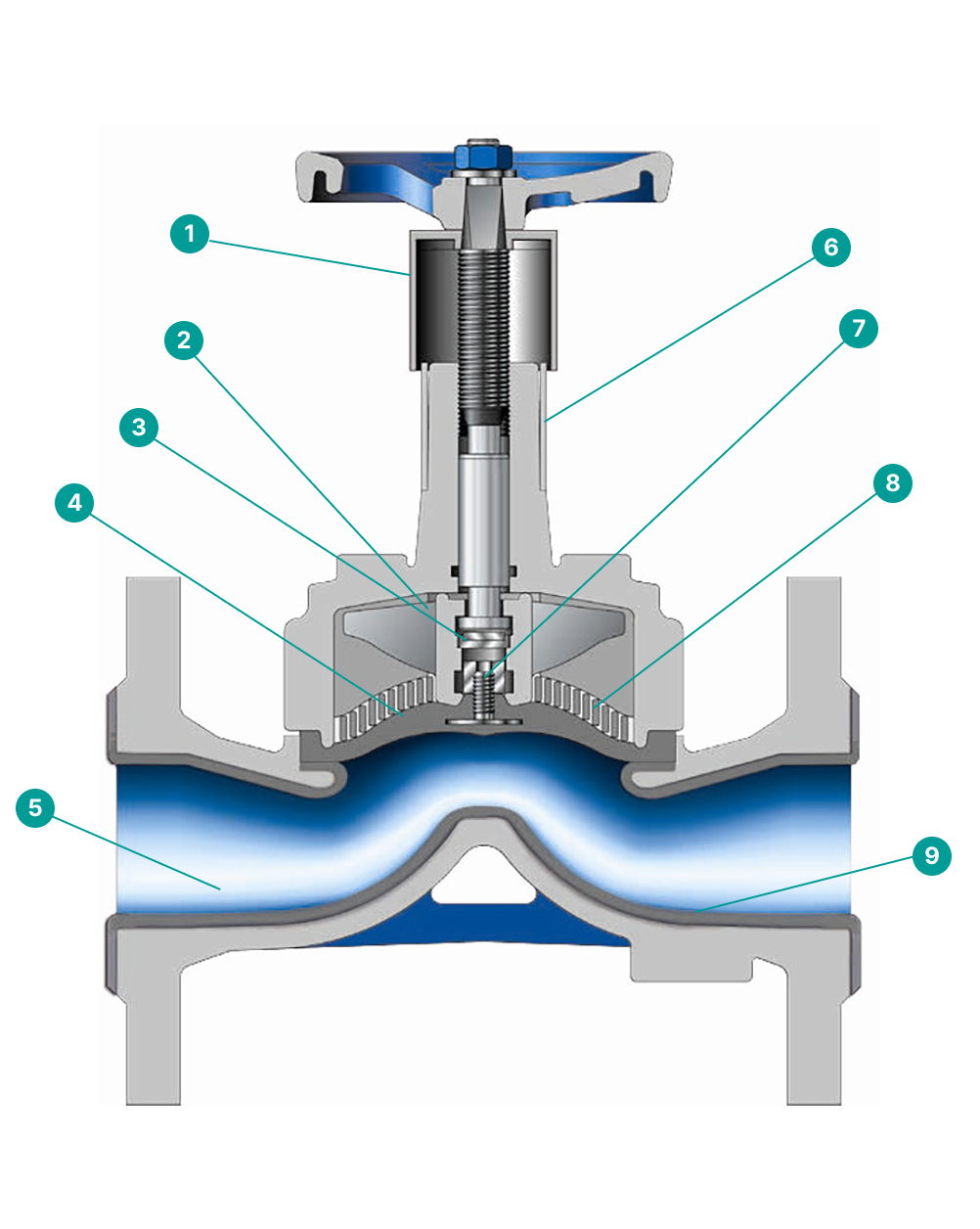

Sisto diaphragm valve type 16

The Sisto diaphragm valve type 16 has been developed for a wide range of liquids and gases. It has a sealing weir and the unique sealing system "chambered diaphragm with spiral support".

Areas of application

- Industrial / process technology

- Power plant technology

- Ore dressing

Typical media

- Industrial water

- Oils

- Acids

- Alkalis

- Technical gases

- Optimized long-term operation

The spindle protection integrated in the position indicator prevents contamination from the outside. - Reliable operability

The spindle and all internal operating parts are not in contact with the medium. - Smooth running

The axial bearing minimizes the closing torques. - Absolute tightness to the outside and in the passage

The diaphragm seals hermetically to the outside, in the passage and the operating parts. - Cleanliness of the flow medium

The absence of dead space ensures cleanliness of the medium and prevents deposits. - Fast position control

Valve position via clear visual indication, easily recognizable even from a distance. - High functional reliability

Balanced diaphragm suspension increases the functional reliability of the diaphragm. - Maximum service life and pressure operating limit

The chambered and spiral-supported diaphragm maximizes the service life and pressure operating limit of the diaphragm. - High corrosion resistance

High quality linings provide safety and durability.

Product data Sisto-16

- Nominal sizes: DN15-300

- Pressure class/max. pressure: PN16/16 bar (from DN250 PN10/10 bar)

- Temperature range: -10°C to +160°C

- Type: straight through with weir

- Overall length: EN558 R1 (ISO 5752/1)

- Body material: cast iron (5.1301)

- Linings: IIR (butyl), NRH (hard rubber)

- Coatings: ECTFE (Halar); Polyamide (Rilsan)

- Diaphragm design: chambered diaphragm with spiral support (from DN250 diaphragm with spiral support)

- Diaphragm materials: EPDM; CSM; NBR; IIR; FKM; TFM/EPDM 2-part; TFM/PVDF/EPDM 3-part

- Actuation: manual, pneumatic, electric