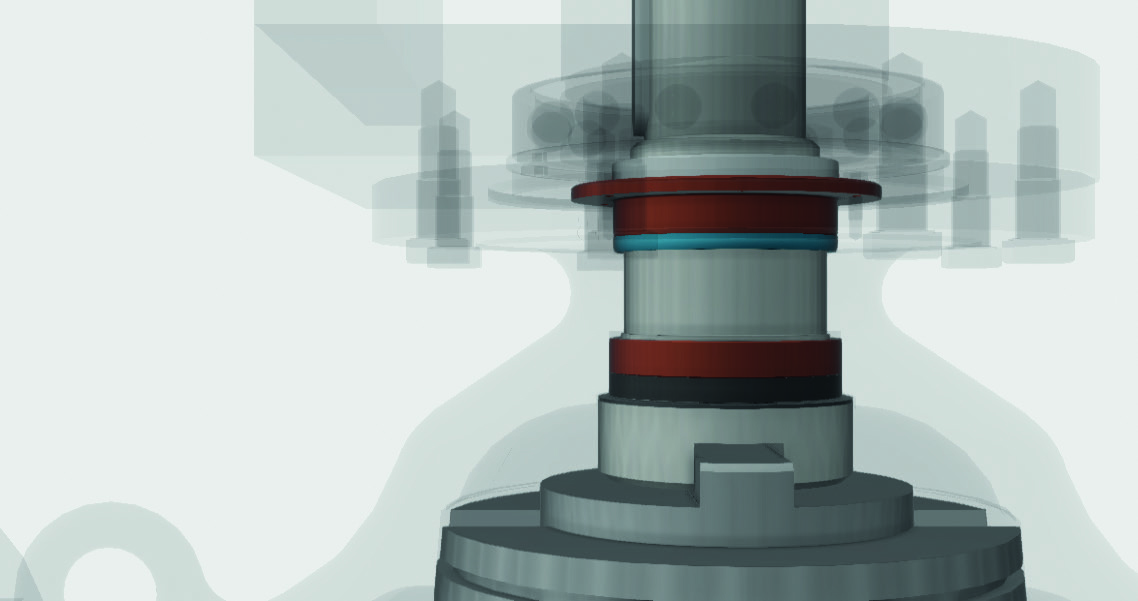

Plug valves by KÄHLER

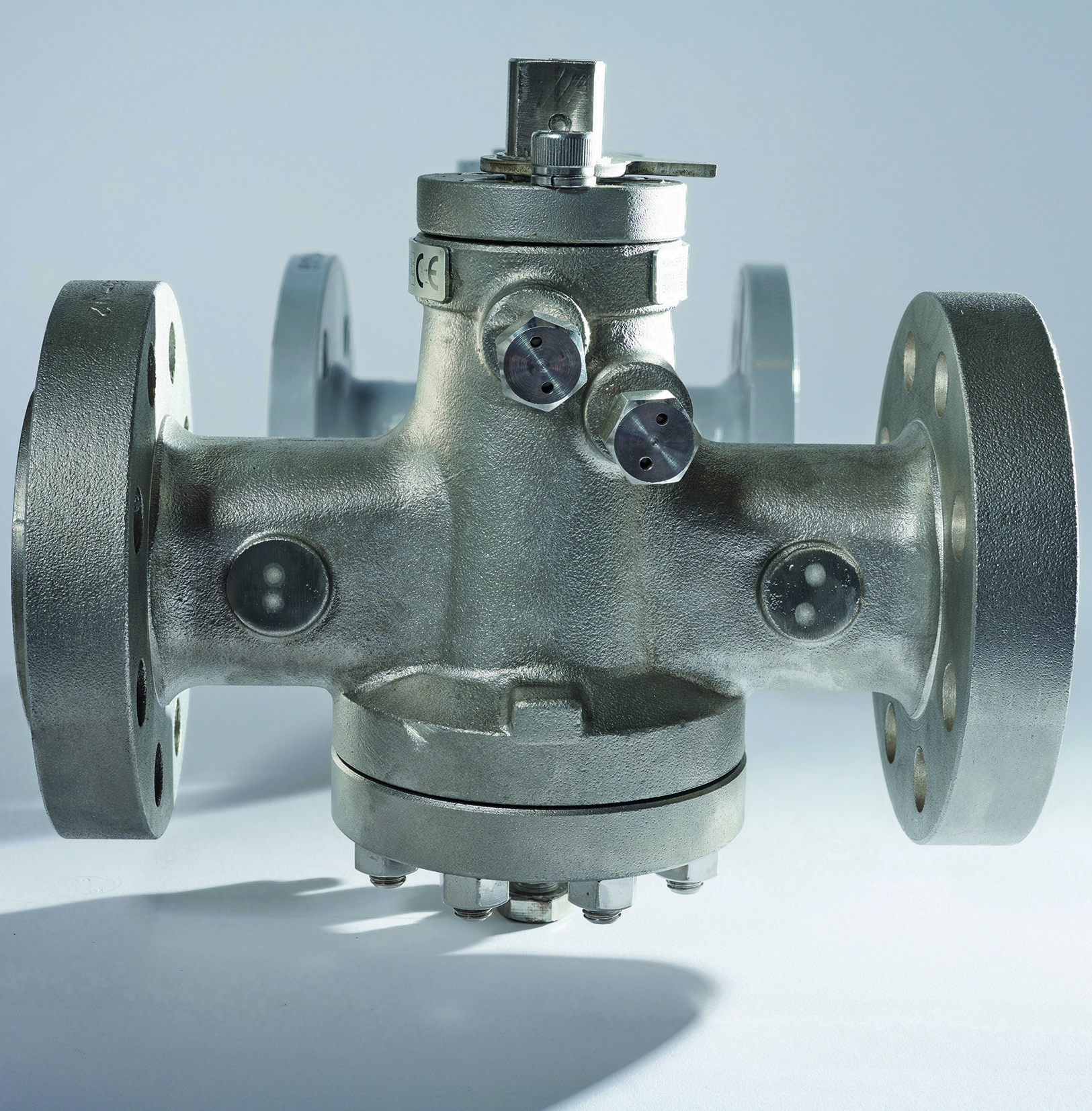

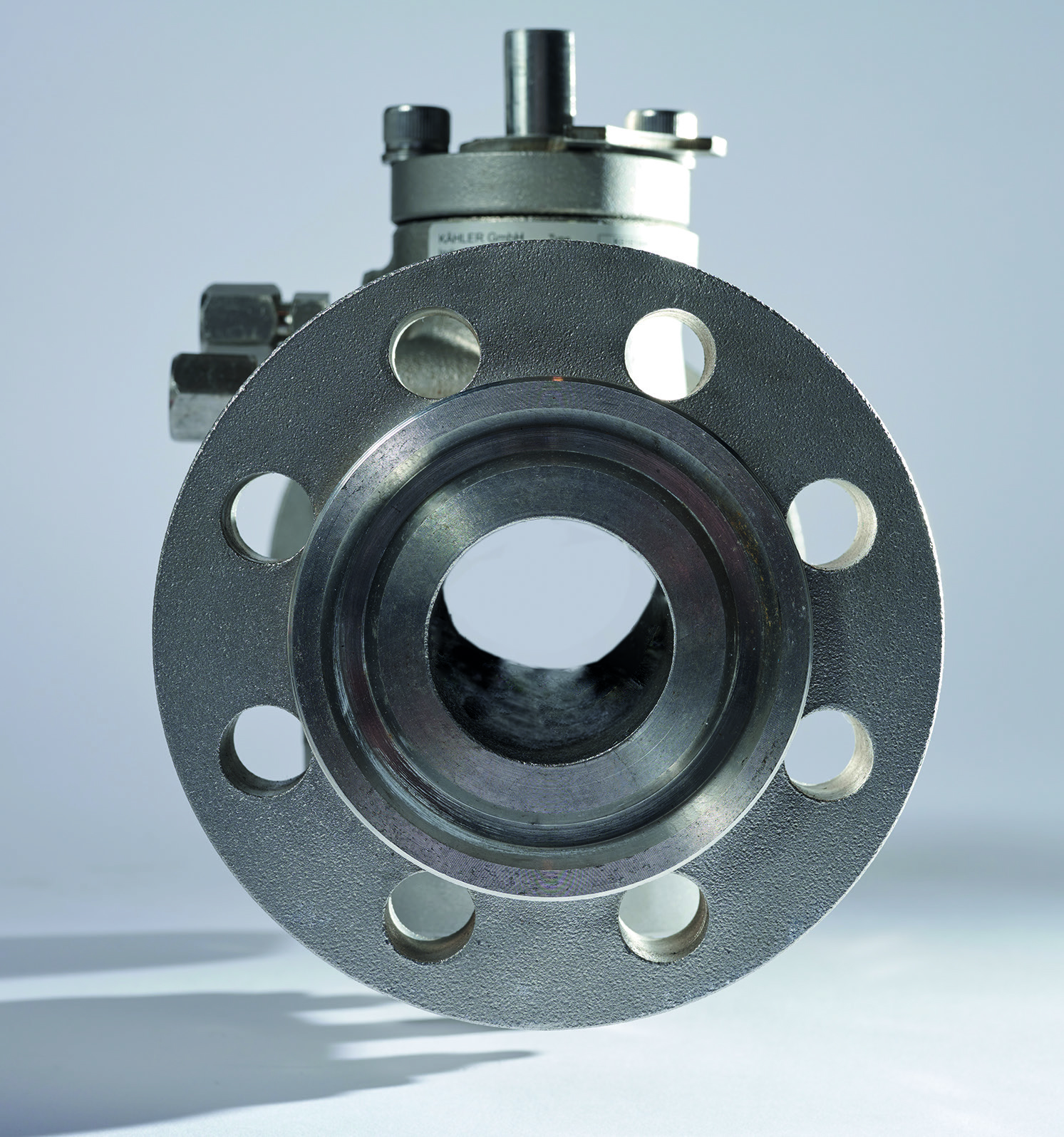

Attractive delivery times and value for money with the highest quality standards characterise KÄHLER products. The two-, three- and four-way plug valves are supplied soft or metal-seated.

Materials: cast iron, steel, stainless steel, duplex, titanium, Hastelloy

Nominal diameters: DN 15 to 900

Pressure classes: PN 6 to 420, class 150 to 2500

Connections: Flange, thread and weld end

Operation: manual, pneumatic, electric

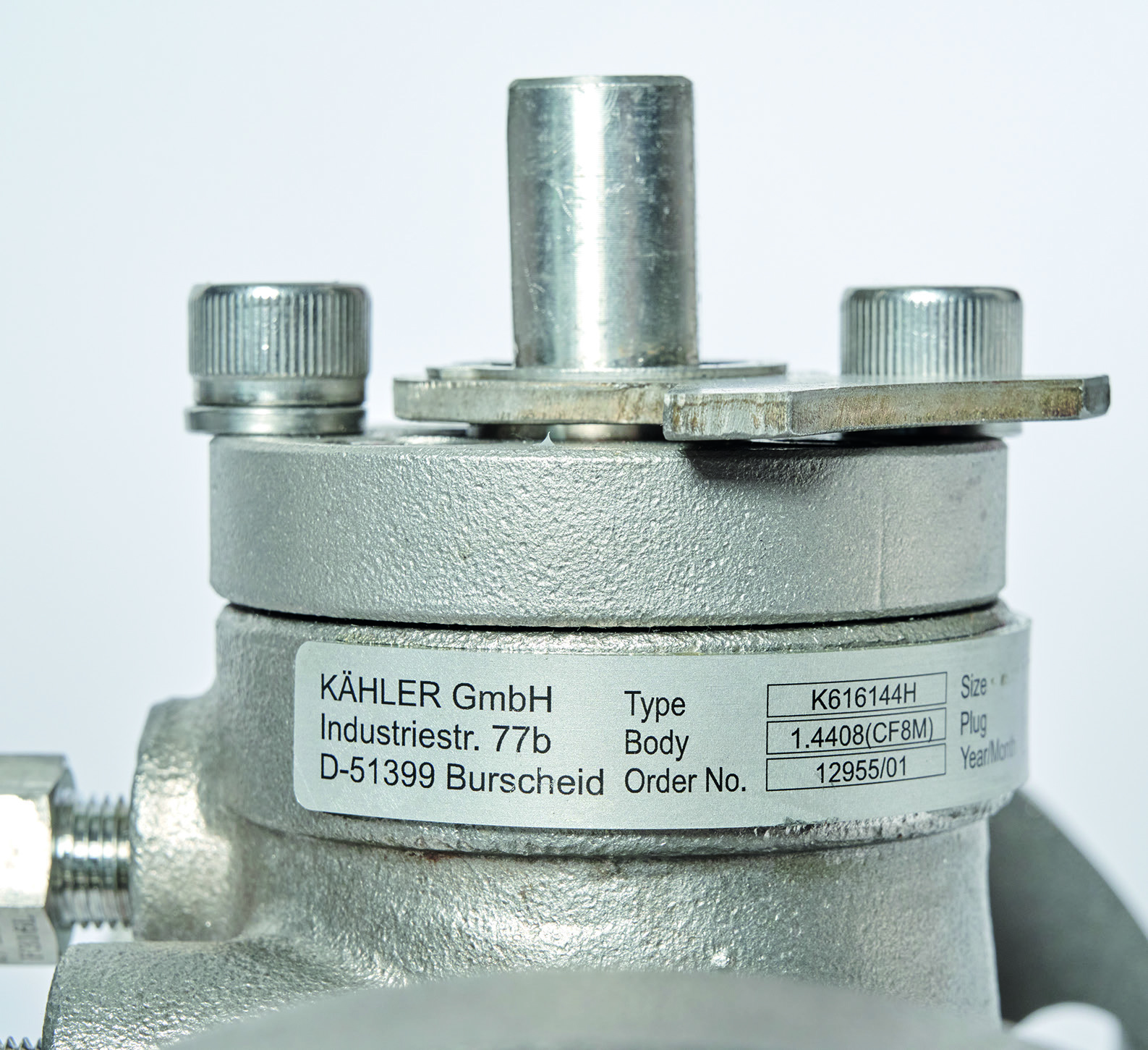

The customer decides - we advise

If you wish, KÄHLER will work out the suitable plug valve together with you. You tell us the pressure, medium, temperature and switching frequency, but also the type of operation. We will then determine your plug valve from over 100 variants. The surface coating - e.g. nickel-plated, PTFE-coated, etc. - still needs to be clarified. We also talk about sealants. Delivery takes 18 to 22 weeks.

You can rely on our After Sales Service

Customer service is important to us. Throughout the entire service life of our valves, KÄHLER employees are there to support the customer with advice and, if necessary, with action. As a manufacturer, we solve technical problems and provide expert advice. We know that after the purchase is before the purchase of another product.

Engineering on top

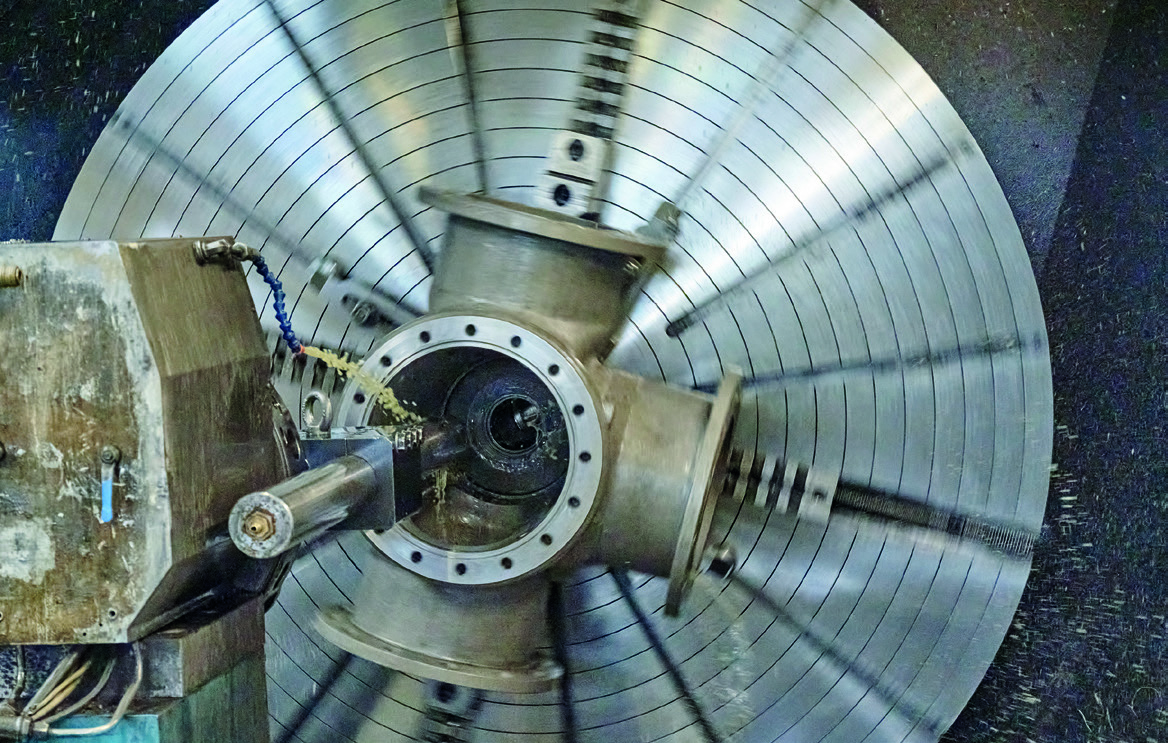

Plug valves from KÄHLER also originate from our own development. We plan and design the valves, give the production clear specifications, monitor the production and guarantee quality control until delivery. We are also the right partner when it comes to extensions, general overhauls and adaptations of existing industrial valves.

Repair? Always!

lug valves are durable valves. Should functional problems arise after many years of intensive use, KÄHLER offers a high-quality repair service together with specialists. We supervise the general overhaul.