Diaphragm valves

Looking for diaphragm valves from SISTO or SAUNDERS?

We offer alternatives and find solutions for your requirements.

Give us a call or write us per email.

phone +49 (2174) 7848 - 0 | email: info@kaehler-armaturen.de

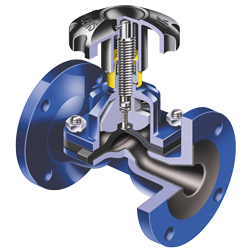

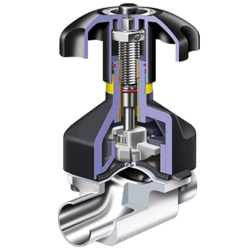

Diaphragm with sealing weir (Sisto type 16/20, Saunders type A)

The diaphragm seals the diaphragm valve on the sealing weir. For this purpose, the diaphragm is only moved over a relatively small distance by means of a pressure piece. The sealing weir comes towards the diaphragm. To open the valve completely, the diaphragm only needs to be deformed slightly. The operating medium only touches the diaphragm surface, all mechanical parts are outside the medium-wetted space. This design is available in plastic and metal. The flow direction is arbitrary.

Areas of application

Use with high-purity (sterile) to heavily contaminated liquid, gaseous as well as neutral and aggressive media. Depending on the design, the application limits are accordingly 10 or 16 bar operating pressure and up to 160°C operating temperature. The flow characteristics are favorable.

Special features and advantages:

All mechanical components are located outside the wetted area. The operating medium only touches the inner surface of the valve body and the surface of the shut-off diaphragm. With pneumatic actuation, the valve is also suitable for increased switching cycles. Appropriate installation angles allow the pipe sections behind the valve to empty as far as possible when the valve is open.

Example areas of application:

Pharmaceuticals, hygiene and sterile technology, semiconductor and microchip production, all areas of water treatment such as wastewater, dirty water, seawater, cooling water and service water as well as ultrapure and pharmaceutical water, sludges, powders and dusts, cellulose and paper production/processing, paint and lacquer production/processing, mining and quarrying technology, gemstone, metal and mineral extraction/processing, fertilizer production, gypsum, cement, sulfur and lime extraction, brine technology, sewage treatment plant technology, granulate production, mechanical and plant engineering, automation technology, food and beverage technology.

Exemplary media:

Industrial and waste water, acids, alkalis, sludges and suspensions.

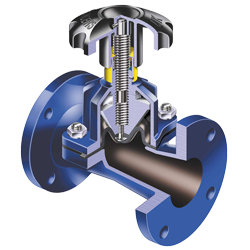

Diaphragm without sealing weir (Sisto type KB, Saunders type KB)

These valves do not have a sealing weir, they have a free passage. This is a flow-optimised housing shape with low flow resistance. Diaphragm valves without a sealing weir are popular due to their robustness.

Expemplary areas of application:

Heavily polluted wastewater, cellulose and paper manufacturing/processing, mining and quarrying technology, gemstone, metal and mineral extraction/processing, fertilizer manufacturing, gypsum, cement, sulfur and lime extraction/processing, sewage plant technology and granulate manufacturing.

Exemplary media:

Industrial water, oils, acids, alkalis, technical gases