Diaphragm Valves with Weir Seat

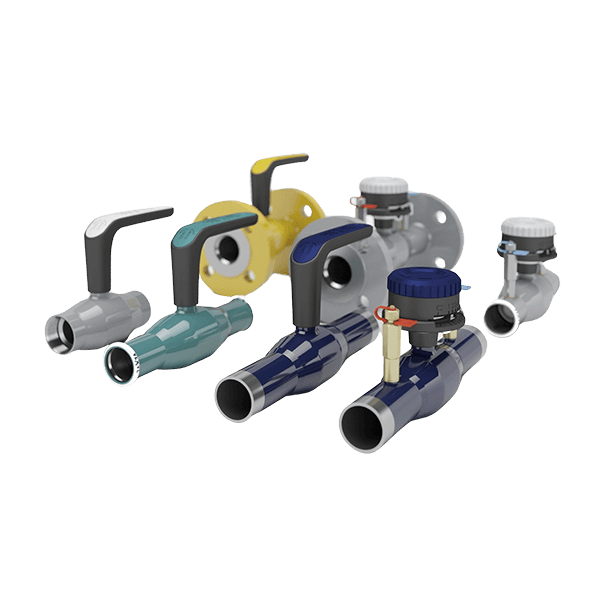

We offer high-quality weir seat diaphragm valves from Crane (Saunders) and Sisto

- known worldwide for innovative and durable solutions in the field of fluid technology.

Our diaphragm valves with weir seat construction in the centre of the valve body

ensure low-wear, flow-optimised and safe operation and therefore a long service life.

They are made of high-quality materials and are characterised by their high reliability, precise control and low dead-space design.

They offer excellent sealing, are chemically resistant, require little maintenance and are suitable for a wide range of industrial applications.

Also in the field of sterile process engineering, where the highest demands are placed on the materials, design and manufacture of the components,

both - Saunders and Sisto - are leaders in the development and manufacture of high-quality diaphragm valves,

which are primarily used in modern biopharmaceutical process systems.

Saunders e.g. manufactures customised bio-block valves from solid material, which also meet complex requirements.

With the development of an innovative sealing system with a chambered diaphragm, Sisto was once again able to set clear trends

in terms of the functionality, safety and durability of diaphragm valves with weir seat.

Our Saunders and Sisto brand diaphragm valves with weir seat are available in a wide range of variants, enabling customised solutions for every application.

In addition to different body shapes, diaphragm types, connection types and actuation options, there is also a wide range of materials available for the body and diaphragm.

Saunders and Sisto diaphragm valves with weir seat can be used in a wide range of industries,

including water and wastewater technology, hygiene and sterile technology, the food and beverage industry, pharmaceutical and biotechnology, the chemical industry,

pulp and paper production, paint and varnish production/processing, gypsum, cement, sulphur and lime production, electronics production and many more.

Applications

diaphragm valve with weir seat

- constructed for many different applications such as industrial and process technology, particularly suitable for difficult applications in pharmacy, hygiene and sterile technology, semiconductor and microchip production, water treatment such as waste water, seawater, cooling water and process water as well as ultrapure and pharmaceutical water, sludge, powder and dust, cellulose and paper production/processing, paint and lacquer production/processing, mining and mining technology, ore processing, gemstone, metal and mineral extraction/processing, fertiliser production, gypsum, cement, sulphur and lime extraction, brine technology, sewage treatment plant technology, power plant technology, granulate production, automation technology, food and beverage technology

- suitable for various media, particularly suitable for clean or low-polluted media or for applications that require high hygiene standards

- robust and reliable even at high pressure and temperatures up to +175°C (depending on material)

- operating conditions according to data sheet

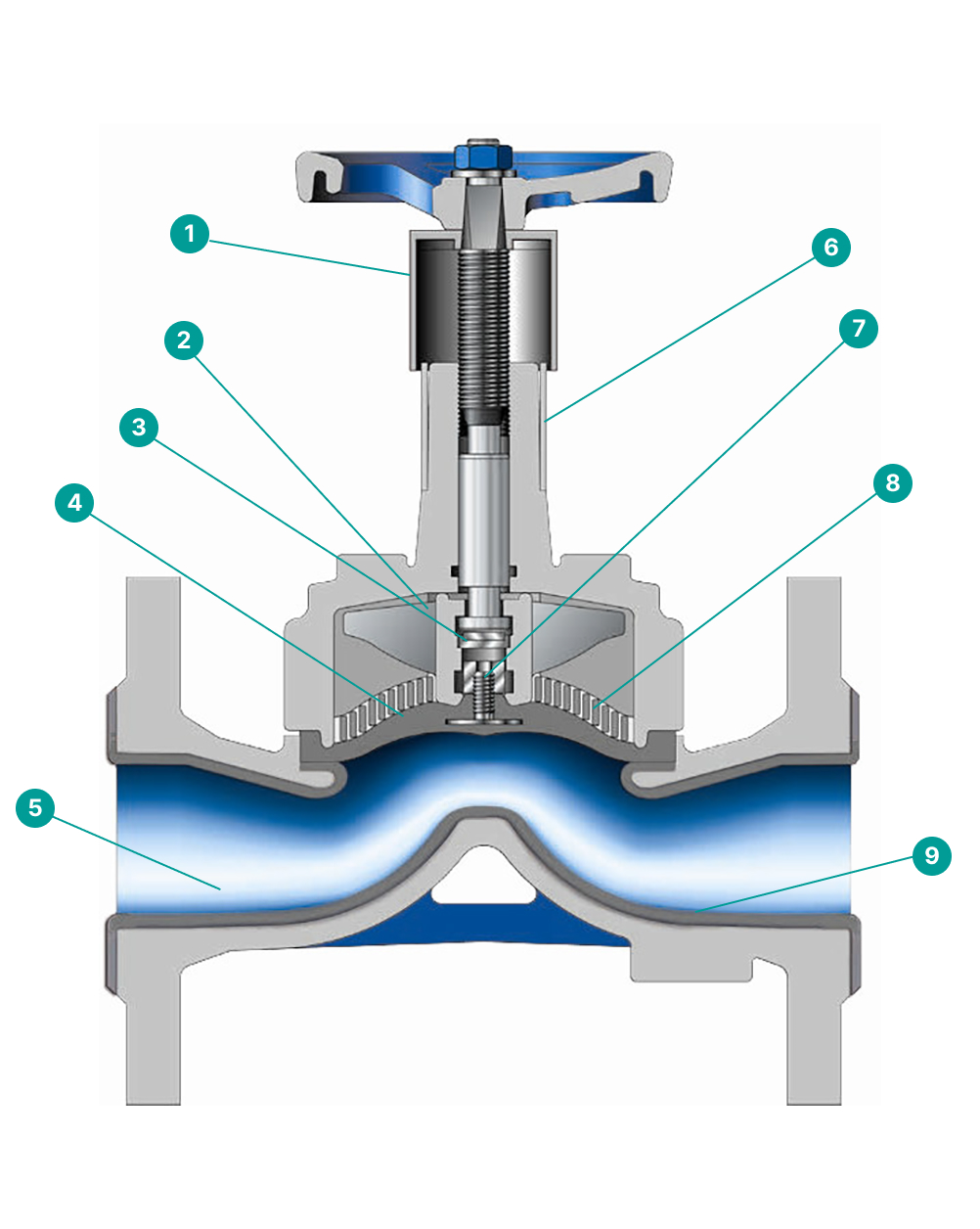

Construction

diaphragm valve with weir seat

- compact, robust, three-piece design with weir seat

- dead-space free and low-maintenance as well as flow- and drainage-optimised design

- valve body made of grey cast iron, ductile cast iron, cast steel, gunmetal or stainless steel, optionally available with coating in a wide range of materials

- internal, flexible shut-off diaphragm made of PTFE, EPDM, Viton, natural rubber or other elastomer materials, can be replaced, even when the valve is installed

- valve top with a handwheel, pneumatic or electric actuator

- highly visible position indicator

- optionally with locking device, limit switch and opening limiter (depending on model)

Versions

diaphragm valve with weir seat

- Nominal sizes:

DN8-350 - Pressure ratings:

PN6, 10, 16 - Connection types:

flange, thread or welding ends, clamp connection - Bore types:

with weir seat - Operation:

optionally available with hand wheel, electric or hydraulic drive

Types and features diaphragm valves with weir seat

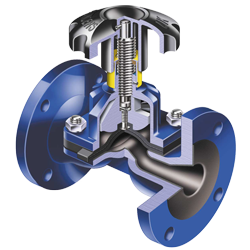

Saunders diaphragm valve type A

- suitable for most industrial applications

- robust, compact design made from high-quality materials

- can be installed in any position, including self-draining if required

- low dead-space, flow-free, drainage-optimised design with permanent lip lubrication for contamination-free operation, uniform flow characteristics and minimal pressure drop

- highly flexible, tight-closing diaphragm for permanent form-fitting shut-off to the outside and in the passage under pressure and vacuum

- low-wear operation of the diaphragm thanks to weir seat construction and supporting compressor

- no cavitation or pressure surges thanks to linear characteristic curve

- uncomplicated and easy operation thanks to ergonomically shaped handwheel and clear position indicator

- low maintenance

- low operating costs thanks to the possibility of replacing the diaphragm without removing the valve from the pipeline

- leak-free operation with long service life

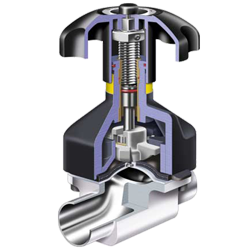

Saunders diaphragm valve AFP

- aseptic, high-purity bio-block valve suitable for biopharmaceutical and related process systems

- robust, compact design made of high-quality forged stainless steel with traceable and tested materials for all components in accordance with FDA (Food and Drug Administration USA) and USP Class VI (United States Pharmacopeia)

- can be installed in any position, including self-draining if required

- low dead-space, flow- and drain-optimised design with standard O-ring seal in the valve bonnet for contamination-free operation, uniform flow characteristics and minimal pressure drop

- no cavitation or pressure surges thanks to linear characteristic curve

- in-house manufactured, highly flexible, tight-closing high-performance diaphragm for permanent, bubble-tight and form-fitting shut-off under pressure and vacuum

- low-wear operation of the diaphragm thanks to weir seat construction and supporting compressor

- uncomplicated and easy operation thanks to ergonomically shaped handwheel and clear position indicator

- optimised design, encapsulated bonnet construction and selected materials for improved external cleaning

- optionally available with locking device, limit switch and opening limiter

- increased safety through maintenance from above while installed

Sisto diaphragm valves type 16 and type 20

- Optimised long-term operation

The spindle protection, integrated into the position indicator, prevents contamination from outside. - Reliable operability

The spindle and all internal operating parts are not in contact with the medium. - Smooth operation

The axial bearing minimises the closing torques. - Absolute tightness to the outside and in the passage

The diaphragm seals the outside, the passage and the operating parts hermetically. - Keeping the flow medium clean

The absence of dead space ensures that the medium remains clean and prevents deposits. - Quick position control

The valve position is easily recognisable even from a distance thanks to the clear visual display. - High functional reliability

The balanced diaphragm suspension increases the functional reliability of the diaphragm. - Maximum service life and pressure limit

The chambered and spiral-supported diaphragm maximises the service life and pressure limit of the diaphragm. - High corrosion resistance

The high-quality coatings offer safety and durability.

This might also interest you:

Give us a call or send us an email

Phone +49 (2174) 7848 - 0 | Email: info@kaehler-armaturen.de | Arrange a consultation